How To Make Glass Wool Work Better ?

Jun 18, 2024

● What is the use of glass wool roll?

● Does glass wool absorb moisture?

● What happens if fiberglass gets wet before it cures?

● Do you need to replace insulation after it gets wet?

● What is another name for glass wool insulation?

Understanding Glass Wool

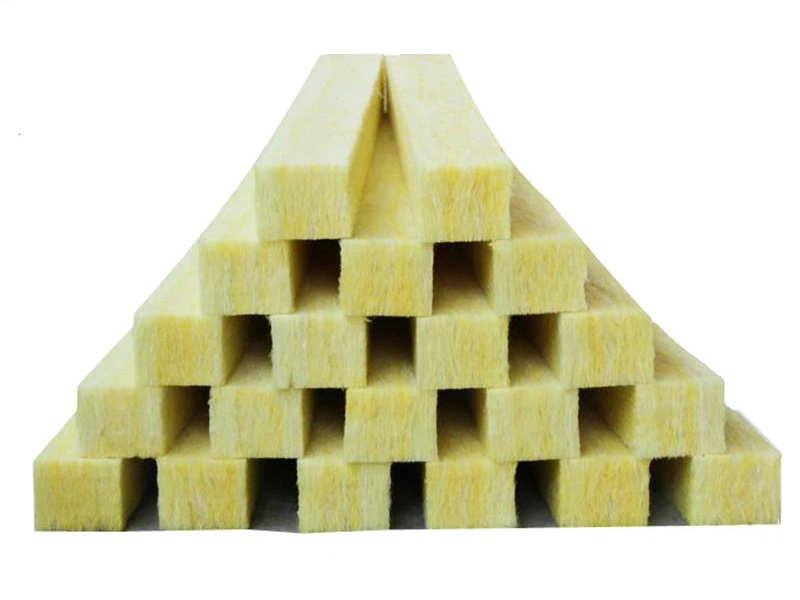

Glass wool is created by melting recycled glass or sand and spinning it into thin strands. After that, a glue is used to fuse these strands together to create a substance that resembles wool. Glass wool is highly valued for its insulating qualities, light weight, and adaptability to a wide range of applications, including home insulation and automotive and aerospace applications.

Safety Concerns and Myths

Glass wool has given rise to a number of safety myths and worries over time, most of which are connected to respiratory issues, skin irritation, and the dangers of prolonged exposure.

Health of the Respiratory System: Breathing in glass wool fibers might lead to respiratory problems. In the past, there have been worries over the inhaled fibers' ability to cause cancer. But a great deal of study and enhanced manufacturing techniques have greatly decreased these risks.

Skin irritation: Coming into close touch with glass wool might irritate your skin. Itching and irritation can result from the fine fibers being buried in the skin. This problem can be lessened with the right safety gear.

Long-term Exposure: It was formerly believed that prolonged exposure to airborne glass wool fibers may cause major health problems, much like asbestos. Regulators have, however, thoroughly investigated this to determine the true risks.

Regulatory Perspective

The following health and safety organizations have assessed the dangers of glass wool:

Organization for World Health (WHO):

Certain varieties of glass wool are not classed as carcinogenic to humans because they belong to Group 3, according to the WHO's International Agency for Research on Cancer (IARC). This categorization implies that there is not enough data to conclude that wearing glass wool causes cancer in people.

The Office for Occupational Safety and Health (OSHA):

To reduce the dangers to employees' health, OSHA offers recommendations for handling glass wool safely and sets exposure limits.

Federal Occupational Safety and Health Administration (NIOSH):

When handling glass wool, NIOSH advises establishing exposure limits and using protective measures to provide a safe working environment.

Ensuring Safe Handling and Installation

To ensure the safe use of glass wool, it is essential to follow proper handling and installation practices. Here are some steps to prove and maintain safety:

1.Use of Personal Protective Equipment (PPE):

- Masks/Respirators: Use N95 masks or higher-grade respirators to prevent inhalation of fibers.

- Gloves: Wear gloves to protect your hands from irritation.

- Safety Goggles: Protect your eyes with safety goggles to prevent irritation from airborne fibers.

- Protective Clothing: Wear long-sleeved shirts and pants to reduce skin exposure.

2.Workplace Practices:

- Ventilation: Ensure that the workspace is well-ventilated to disperse airborne fibers.

- Clean-Up: Wet clean-up methods or HEPA-filtered vacuum cleaners should

- be used to clean up any glass wool dust and fibers.

3.Modern Product Choices:

- Low-Dust Products: Opt for modern glass wool products designed to generate less dust and fiber release.

- Coated Fibers: Some glass wool products are manufactured with coatings that reduce fiber release and irritation.

4.Training and Awareness:

- Education: Provide training for workers and installers on the proper handling and installation of glass wool.

- Safety Protocols: Establish and enforce safety protocols to ensure compliance with protective measures.

2. What is the use of glass wool roll?

Faced Glass Wool in Rolls are a common and adaptable insulating material with superior acoustic and thermal qualities. It is made of fine glass fibers and rolls out and cuts readily to meet a variety of uses. It is a flexible material that resembles a blanket. This blog examines the functions of glass wool rolls and emphasizes the advantages of each use.

Uses of Glass Wool Roll

Thermal Insulation:

- Buildings: Glass wool rolls are frequently used in both residential and commercial buildings to insulate the floors, walls, and roofs. Glass wool greatly minimizes heat transfer by trapping air inside its fibers, which helps to maintain constant indoor temperatures and lessens the demand for heating and cooling.

- Pipes and Ductwork: In HVAC (Heating, Ventilation, and Air Conditioning) systems, insulation is also utilized to reduce heat gain or loss and increase energy efficiency.

Sound Absorption:

- Soundproofing Walls: Both external and interior walls can be effectively soundproofed with glass wool rolls, which lessens noise transfer from outside sources and between rooms. They are therefore perfect for usage in public spaces, offices, homes, and recording studios.

- Ceilings and Floors: They can also be used in ceilings and floors to minimize impact noise and airborne sound, creating a quieter and more comfortable environment.

Fire Safety:

- Fire Resistance: Glass wool is a useful material for improving fire safety in structures since it is non-combustible and can tolerate high temperatures. It aids in containing and slowing the progress of the fire, giving firefighters and evacuation teams vital time.

- Glass wool rolls are used in industrial settings to insulate machinery and equipment, preventing fires and preserving acceptable operating temperatures.

Air Conditioning Systems:

- Duct Insulation: To improve the efficiency of heating and cooling systems and avoid energy loss, glass wool rolls are used in HVAC systems to insulate ducts. This guarantees that heated or cooled air will not be lost during transit.

- Noise Reduction: They also help to reduce noise generated by the movement of air through ducts, contributing to a quieter indoor environment.

Manufacturing and Industry:

- Equipment Insulation: To maintain ideal operating temperatures and increase energy efficiency, glass wool rolls are used to insulate industrial equipment like boilers, ovens, and kilns.

- Process Piping: They also help regulate the temperature of transported fluids and gases by insulating process piping in a variety of industries.

Benefits of Using Glass Wool Roll

Energy Efficiency

Thermal Performance: By limiting heat gain in the summer and loss in the winter, glass wool's superior thermal insulation qualities contribute to lower energy usage. As a result, there is a decrease in energy costs and carbon emissions.

Cost Savings: Glass wool insulation is a cost-effective insulation option since it increases the energy efficiency of structures and systems, which leads to considerable cost savings over time.

Acoustic Comfort

Noise reduction: Glass wool's ability to absorb sound makes it a perfect material for lowering noise levels and improving acoustic comfort. This is especially helpful in business buildings, heavily populated locations, and other settings where noise control is crucial.

Enhanced Privacy: Glass wool insulation helps to create quieter, more tranquil living and working areas by minimizing sound transmission between rooms.

Fire Safety

Non-Combustible: Glass wool is a safe insulation option that adds to the general fire safety of commercial and residential buildings due to its non-combustible nature.

Enhanced Protection: It helps contain the fire by slowing its progress, protecting people and property more thoroughly, and buying emergency responders more time.

Versatility and Ease of Installation

Non-Combustible: Faced Glass Wool in Rolls are a safe insulation option that adds to the general fire safety of commercial and residential buildings due to its non-combustible nature.

Enhanced Protection: It helps contain the fire by slowing its progress, protecting people and property more thoroughly, and buying emergency responders more time.

Environmental Benefits

Recyclability: Glass wool is an environmentally friendly insulating material because it is composed of recycled glass and sand. Its application encourages sustainable building methods and waste reduction.

Longevity: As glass wool insulation is strong and resilient, it keeps working for a long time, lowering the need for regular repairs and promoting sustainable building upkeep.

3.Does glass wool absorb moisture?

Does Glass Wool Absorb Water?

Faced Glass Wool in Rolls doesn't often absorb water. Because glass strands are braided together to form its structure, it is naturally moisture-resistant. The main causes of this resistance are the arrangement of the fibers and the non-porous nature of glass. Glass wool holds its shape and insulating qualities when wet, which makes it a dependable material for areas where moisture may be an issue.

Structure

The structure of glass wool is crucial in understanding its moisture resistance

Glass wool's fibrous composition is made up of many tiny glass threads that intertwine to form a network of tiny air pockets. Its insulating qualities are enhanced by these air spaces, which also prevent water absorption.

Water cannot pass through the fibers of glass since it is not porous in and of itself. This feature guarantees that the glass wool will not absorb water even if its surface comes into contact with it.

During the manufacturing process, a lot of glass wool items are given a hydrophobic agent treatment. By keeping moisture off the surface, these treatments improve the material's resistance to water even further.

Benefits

The moisture-resistant properties of Faced Glass Wool in Rolls offer several benefits

Maintained Insulation Efficiency

Even in damp environments, glass wool retains its ability to insulate against heat and sound since it does not absorb water. Glass wool performs the same as other insulating materials, although moisture can weaken them by making them more thermally conductive.

01

Durability

Glass wool's resistance to moisture guarantees that it works for a long time, lowering the need for regular maintenance or replacements. Because of its longevity, it's an affordable insulating option.

02

Preventing Mold and Mildew

Water-absorbing materials can turn into havens for mold and mildew, which can pose health risks and cause structural damage. Because glass wool resists moisture, it helps stop this kind of growth and promotes healthier indoor conditions.

03

Fire Resistance

Glass wool's fire-resistant properties are not compromised by moisture. Some insulation materials may lose their fire-resistant capabilities when wet, but glass wool maintains its integrity, providing consistent fire protection.

04

How to Make Better Use of the Structure of Glass Wool

The following advice can help you get the most out of glass wool's moisture-resistant qualities:

- Correct Installation: Make sure that the glass wool is put in place appropriately, without any gaps or compressions that can affect how well it works. Installing the material correctly keeps it from becoming ineffective and stops moisture from seeping in through installation errors.

- Use in Appropriate Applications: Glass wool can be used in a number of places, such as around HVAC systems, in roof spaces, and in wall cavities. Because of its resistance to moisture, it's especially helpful in damp spaces like bathrooms and basements.

- Complementary Materials: To improve glass wool's effectiveness in high-humidity settings, combine it with vapor barriers and other moisture-controlling techniques. In order to further shield the insulation from possible water exposure, vapor barriers can keep moisture from penetrating the material.

- Frequent Inspections: Make sure that no water is getting into the space by periodically checking the insulated parts. To preserve the integrity of the insulation, look for leaks or damage to the building envelope that can allow moisture to enter the structure. Take quick action to fix any problems you find.

- When hydrophobic treated Faced Glass Wool in Rolls goods are available, cho

- ose them, particularly for situations where water exposure is a problem. These coatings offer an extra degree of moisture resistance.

4.What happens if fiberglass gets wet before it cures?

The Importance of Curing in Fiberglass

Curing is the process by which the fiberglass's resin solidifies and forms a link with the glass fibers to produce a sturdy, long-lasting substance. This procedure turns the liquid resin into a solid state by a chemical reaction that is usually started by a catalyst or hardener. The mechanical qualities of fiberglass, such as strength, stiffness, and resistance to external influences, must be achieved by correct curing.

Effects of Moisture on Uncured Fiberglass

When fiberglass gets wet before curing, several issues can arise

Incomplete Curing

Chemical Reaction Disruption: The chemical reaction that the resin needs to cure correctly can be hampered by moisture. Water has the ability to impede the polymerization process, resulting in insufficient curing.

Weak Bonding: The resin may not be able to properly connect with the glass fibers in the presence of water, which will make the composite material weaker.

Reduced Mechanical Properties

Reduced Strength: Before curing, fiberglass that has been exposed to moisture frequently shows signs of diminished mechanical strength. This is a result of the resin's incomplete hardening, which compromises the composite's structural integrity.

Reduced endurance: The fiberglass may become more prone to cracking, delamination, and other types of degradation, which could threaten its long-term endurance.

Surface Imperfections

Bubbles and Voids: When water that has been trapped in the resin evaporates or interacts with the curing process, bubbles and voids may occur. These flaws make the material weaker and lead to failure sites.

Uneven Surface: The appearance and functionality of the fiberglass may be impacted by an uneven surface finish caused by the presence of moisture.

Increased Risk of Delamination

Layer Separation: Delamination or separation of the fiberglass layers can be brought on by moisture. The strength and structural integrity of the composite are greatly diminished by this separation.

Preventing Moisture Exposure

Fiberglass must be shielded from moisture throughout the curing process in order for it to cure correctly. Here are a few precautionary steps to take:

1. Controlled Environment:

Indoor Curing: To reduce exposure to moisture and humidity, cure fiberglass indoors in a controlled atmosphere whenever feasible.

Humidity Control: Particularly in regions with high humidity, use dehumidifiers to regulate the humidity levels in the curing area.

2. Preventive actions:

Covering: To keep the fiberglass safe from rain and moisture, cover it with tarps or plastic sheeting.

Sealing: To avoid water seeping in during the curing process, make sure molds and forms are adequately sealed.

3. Correct Storage:

Dry Storage: Keep uncured fiberglass products out of the way of any possible moisture sources.

Packaging: To avoid moisture absorption, keep resin and other curing chemicals in sealed containers.

Addressing Wet Fiberglass Before Curing

If fiberglass gets wet before it has cured, there are steps you can take to mitigate the damage

Drying

Take prompt action to extract as much water as you can. Utilize a fan to accelerate drying and absorbent materials to wipe the surface.

Application of Heat: Using a little heat source can occasionally aid in the evaporation of moisture, but take care not to burn the resin by overheating it.

Assessing Damage

Inspection: After the fiberglass has dried, check it for any indications of delamination, bubbles, or incomplete curing.

Testing: To evaluate the material's strength and integrity, subject a small part to mechanical tests.

Repairing

Application of Resin: To reinforce weak locations and fill in gaps, add more resin to areas with small defects.

Reinforcement: To strengthen the regions that have sustained severe damage, think about adding more layers of fiberglass.

5.Do you need to replace insulation after it gets wet?

In order to keep your home comfortable and energy efficient, insulation is essential. By minimizing heat transfer, it keeps your house cool in the summer and warm in the winter. Nevertheless, insulation may lose some of its effectiveness if it becomes wet.

Why Wet Insulation Occurs

Wet insulation can occur for a number of reasons:

- Roof Leaks: Water can penetrate faulty roofing and soak into the ceiling or attic's insulation.

- Plumbing Leaks: Water damage to insulation in walls or ceilings can result from broken or leaking pipes.

- Flooding: Appliance malfunctions or natural disasters can cause flooding, which can wet insulation in crawl spaces or basements.

- Condensation: In places like attics, poor ventilation can lead to condensation, which can result in moist insulation.

Because moisture lowers an insulation's thermal resistance, or R-value, it can have a substantial effect on how well it performs. An insulation material's resistance to heat flow is measured by its R-value; the higher the R-value, the better the insulation. The efficiency of insulation is decreased when it becomes wet because the water moves the air within the material. The impact of moisture on various types of insulation is examined here:

Insulation made of fiberglass

When dry, fiberglass insulation, which is composed of tiny glass fibers, is very effective. Nevertheless, since water replaces air in the fibers when it gets wet, it loses its insulating qualities. Mold development can result from wet fiberglass insulation, which is dangerous to one's health.

Insulation Made of Cellulose

Recycled paper products that have been treated with fire retardants are used to make cellulose insulation. Its high absorption capacity and ability to retain moisture cause the R-value to significantly decrease. Additionally, cellulose insulation may degrade and settle after extended exposure to moisture, which will lessen its efficiency.

Insulation using Foam

Fiberglass and cellulose insulation are more vulnerable to water damage than spray foam and rigid foam board insulation. Still, these materials may deteriorate if exposed to moisture for an extended period of time. Although open-cell and closed-cell spray foam can both become damaged by prolonged contact to moisture, closed-cell spray foam has a higher water resistance.

Hazards Associated with Retaining Wet Insulation:

1. Mold Development

Mold growth is one of the biggest dangers associated with leaving moist insulation in place. Mold may swiftly spread and thrive in moist conditions, which can cause health problems like allergies, asthma, and other respiratory disorders. The building's structural integrity may potentially be harmed by mold.

2. Diminished Energy Effectiveness:

Higher energy expenditures result from wet insulation's diminished ability to insulate. This is due to the ineffective air-tightness of the wet insulation, which permits heat to exit during the winter and enter during the summer, increasing the workload of the heating and cooling systems.

3. Damage to Structure:

Over time, moisture can lead to structural damage to the building. Wet insulation can cause deterioration of building materials, metal component corrosion, and wood rot. This may jeopardize the building's structural stability.

When to Change Soaky Insulation

1. Moisture Exposure Amount:

When deciding whether to replace insulation, the degree and duration of moisture exposure are important considerations. It is usually advised to replace insulation that has been fully saturated or exposed to prolonged moisture. Thorough drying may be able to mitigate minor, transient exposure, but this needs to be carefully evaluated.

2. Insulation Type:

The way that various insulating materials react to moisture varies. For instance, fiberglass insulation may be dried out even if it is only slightly damp, but because cellulose is absorbent, it frequently needs to be replaced. Closed-cell foam insulation in particular may not require replacement unless there is extensive water damage.

3. Mold Is Present:

It is essential to replace the insulation if mold is found. In addition to negatively impacting the insulation's effectiveness, mold presents significant health hazards. Mold can develop and spread even in seemingly dry insulation.

4. Issues with Structure:

It is imperative to replace the insulation and fix the structure if there are any indications of structural damage, such as wood rot or weakened construction components. Over time, allowing damaged insulation to remain in place can make these problems worse.

What to Do If Your Insulation Gets Wet

Locate and Address the Moisture Source:

Determine and address the source of the moisture before treating the wet insulation. This can be a plumbing problem, insufficient ventilation, or a leak in the roof. In order to avoid more issues, the moisture source must be fixed.

Evaluate the harm:

Determine how much water damage there is. Look for indications of structural damage, mold, and mildew. Find out what kind of insulation has been impacted and for how long the insulation has been wet.

Empty or Switch Out:

You might not need to replace the insulation if the damage is modest and it can be dried completely. Replacing the insulation is advised, though, if it is severely saturated, exhibits mold, or has been damp for a long time.

Expert Examining:

Think about getting an expert to look over the damage. They are able to offer a comprehensive analysis and suggest the best line of action. Experts possess the equipment and knowledge necessary to assess the damage and guarantee effective restoration.

6.Can Glass Wool Be Reused?

Glass wool, a popular insulation material, is renowned for its excellent thermal and acoustic properties. With increasing environmental awareness, many people are considering the reuse of building materials to reduce waste and conserve resources.

Understanding Glass Wool

Glass wool, also known as fiberglass insulation, is made from recycled glass and sand, which are spun into fine fibers. This material is commonly used for thermal insulation, acoustic insulation, and fire resistance in buildings. Products include glass wool insulation material, acoustic glass wool insulation, resin bonded glass wool, and resin bonded fiber glass wool.

Can Glass Wool Be Reused?

glass wool can be reused under certain conditions. Its reusability depends on factors such as the condition of the material, the original installation environment, and the intended new use.

Reusability

Durability: Glass wool is durable and maintains its structural integrity over time if it has been kept dry and free from contaminants.

Performance: The thermal and acoustic performance of resin bonded fiber glass wool. remains effective if the fibers are intact and the material has not been compressed or damaged.

Why Reuse

Environmental Impact: Reusing glass wool reduces the demand for new raw materials, minimizes waste, and supports sustainable building practices.

Cost Savings: Reusing insulation material can lower project costs, making it an economical option for builders and homeowners.

Safety Considerations for Reusing Glass Wool

'lt is awesome to work with Creative. amazingy organized,easy to communicate with. responsive with next iterations,and beautiful work

Contamination Risks

Before reusing glass wool, it is crucial to ensure it has not been contaminated by mold, chemicals, or other hazardous substances. Contaminated insulation can pose health risks and reduce indoor air quality.

Structural Integrity

Inspect the resin bonded glass wool for any signs of damage, such as compression or tearing. Damaged fibers can compromise the insulation's effectiveness and should not be reused.

Moisture Exposure

Glass wool that has been exposed to moisture may harbor mold or mildew. Wet insulation should be thoroughly dried and inspected for mold before considering reuse. If mold is present, it is unsafe to reuse the material.

Health and Safety

Handling glass wool requires safety precautions to prevent skin irritation and respiratory issues. Always wear protective clothing, gloves, and a mask when inspecting and handling reused glass wool.

Guidelines for Reusing Glass Wool

Source from Reliable Suppliers

Make sure the recycled glass wool you buy comes from a reliable source, such as a glass wool factory or manufacturer. This guarantees that the material satisfies performance and safety requirements.

Proper Storage

Store glass wool in a dry, clean environment to prevent contamination and damage. Proper storage extends the lifespan and usability of the insulation.

Professional Assessment

Consult with professionals to assess the condition of the glass wool. Experts can determine if the material is suitable for reuse and provide guidance on safe handling and installation.

Reinstallation

When reinstalling reused glass wool, ensure it is installed correctly to maintain its insulating properties. Follow manufacturer guidelines and local building codes to ensure compliance and effectiveness.

7.What is another name for glass wool insulation?

Glass wool insulation, commonly known as fiberglass insulation, is a widely used material in the construction industry. This term and its variations reflect the material's composition and properties. Let's explore where these names come from, whether they have different meanings, and what each represents.

- Origin: The term "glass wool" comes from the manufacturing process, where glass is melted and spun into fine fibers, creating a wool-like texture.

- Meaning: This name emphasizes the material's origin (glass) and its wool-like appearance.

2. Fiberglass Insulation:

- Origin: The term "fiberglass" combines "fiber" and "glass," highlighting that the material consists of fine glass fibers.

- Meaning: This name focuses on the structure of the insulation, made up of glass fibers. It is the most commonly used name in North America.

3. Glass Fiber Insulation:

- Origin: Similar to "fiberglass," this term explicitly states that the insulation is made from glass fibers.

- Meaning: While less commonly used than "fiberglass," it is sometimes preferred in technical contexts to specify the material composition.

Differences in Meaning and Representation

Although these names generally refer to the same material, slight differences in usage and context can be observed:

Glass Wool Insulation:

- Usage: More commonly used in Europe and Asia. It is often preferred by glass wool manufacturers, glass wool factories, and China glass wool manufacturers.

- Context: Emphasizes the product's wool-like texture and appearance, which is a result of the spinning process.

Fiberglass Insulation:

- Usage: Predominantly used in North America. It is the term most familiar to consumers and industry professionals in the United States and Canada.

- Context: Highlights the material's fibrous structure, which is crucial for its insulating properties.

Glass Fiber Insulation:

- Usage: Less common in everyday use but can be found in technical documents and specifications.

- Context: Focuses on the material composition, making it clear that the insulation consists of glass fibers.

Practical Implications

While these terms are often used interchangeably, understanding their origins and slight contextual differences can be useful:

- Marketing and Sales: Manufacturers and wholesalers might choose one term over another based on regional preferences and market trends. For example, a China glass wool manufacturer might use "glass wool insulation" in their branding to align with local and international markets.

- Technical Specifications: In technical documents and product specifications, "glass fiber insulation" might be used to avoid ambiguity and clearly describe the material composition.

- Consumer Communication: For consumer-facing information, "fiberglass insulation" might be used in North America due to its familiarity, whereas "glass wool insulation" might be more recognizable in other regions.